Design & plan

Design and plan your log house or round log structure with us. Any dream or idea is possible when you build with logs. Please contact us with enquiries well in advance, so we can advise on options and possibilities and their impacts on costs etc. After determining your budget and desires, we will then continue with the steps outlined below:

1: Understanding & design brief

A member of our team will visit your site to discuss and understand the opportunities and constraints of your project. Views, local materials, prevailing weather, and shading can all be assessed at this stage. Through a process of structured questioning we will try and help draw out the details of what really matters to you.

2: Concept designs to Planning drawings

Having gathered as much information as possible from the consultation at your site, we will design a proposed concept model for your project. Sometimes this is a fairly straight forward development of a design from the brief, on other occasions this involves exploration of a number of options at a sketch level which helps focus clients decisions and reduce subsequent design changes. An indication of project cost becomes meaningful once you are happy with the concept design. At this point we will be able to give a quote for finalizing the design and preparing drawings for a planning application (if applicable).

3: Building warrant drawings & detailed costing

Once planning is granted, and If building warrant is required we can begin preparing the more detailed drawings for a structural engineer to certify and submit to building control. A SAPS report may also be required and we can help obtain these for your project.

Once final design drawings are complete we are able to estimate for construction of your project.

4: Construction

The logs will be sourced from the highlands and taken to our yard where they will be assessed and categorized so that their characteristics can be best used within the build. After de-barking and peeling each log is marked, cut and scribed into position. Floor, wall and roof components will all be made and assembled in the workshed, and you are welcome to visit at any stage. Sawn timber components such as sarking, cladding and floorboards can be milled in house or brought in, depending on design requirements. The window and door requirements are finalised and ordered.

The building is then disassembled, and drilling out for concealed wiring and flush fit electrical boxes etc, along with fitting of P gaskets, is undertaken before all the parts are moved to your site. Site preparation can be undertaken whilst building is underway in the shed.

On site, we assemble the structural log work rapidly to a wind and water tight stage. We can continue the build to a turnkey finished project or you may choose to finish the project yourself or with local contractors. All are good options and the best for you depends on many factors and is decided on a project by project basis at the planning and costing stage.

Extract from design brief layout to explore impacts

Extract from Round House elevation drawings

Extract from Round House structural frame drawings

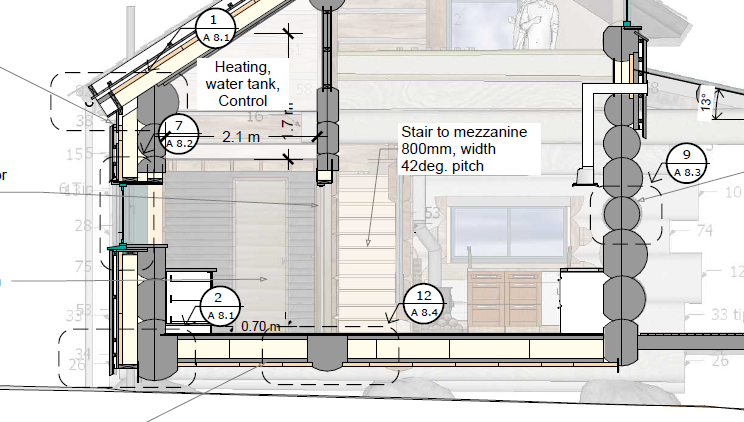

Extract from Small Log House Section